Like all biochemical processes, we can evaluate fermentation performance using the following 3 Key Performance Indicators (KPIs): productivity, yield and titer. These 3 KPIs have a direct impact on industrial ethanol production cost and thus plant profitability.

All fermentation stresses leading to an impact on one or several of these KPIs will also impact plant profitability. Therefore, understanding the fermentation stresses that influence performances in an industrial ethanol plant is key. It will allow to define optimized fermentation process parameters leading to a direct plant profitability increase.

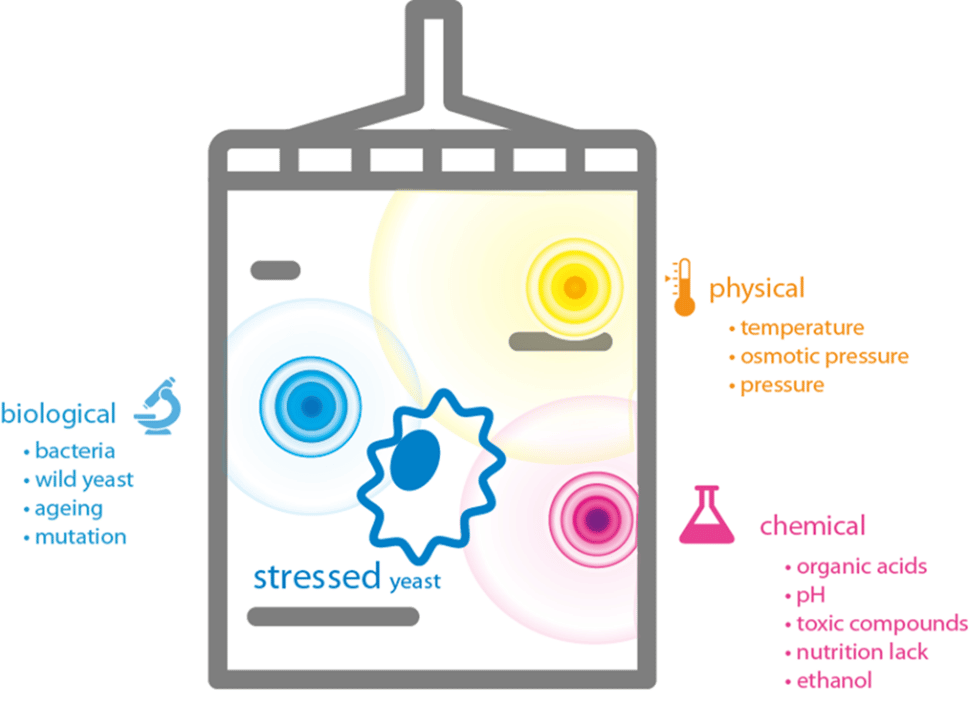

Fermentor is a stressful place for the yeast

In a fermentor, yeast will face 3 types of stress: biological, physical and chemical stress.

Biological stresses during fermentation

Contamination by bacteria (and possibly wild yeast for some raw materials such as beet) can happen in the fermentor. The growth competition between the yeast pitched and the contaminants is causing this contamination in the fermentor. Bacteria can double its population in 20 minutes. This means that every hour the bacteria population can be multiplied by 23=8. Yeast, on the other hand takes 2 hours to double its population, which is 6 times less than bacteria (8/1.4=6). There is thus a fierce race between the different microorganisms to access substrates. Minimizing the initial contaminant population with a smart choice of process parameters will decrease the bacteria growth rate (pH, temperature, …). This will provoke less stress and thus increase plant profitability.

Another occurring stress is ageing, a phenomenon happening after 10 to 20 yeast generations. Each division (budding cycle), leaves budding scars that will affect the yeast’s growth rate. If the growth rate decreases, the ethanol productivity will also decrease. This phenomenon will not typically occur in batch process in which yeasts go through 8 generations. However, in continuous fermentations, yeasts go through multiple division cycles and fermentations will be affected without repitching. Adapted pitching of the yeast in continuous process could overcome the loss of fermentation kinetics (fermentation speed).

Physical stresses affecting fermentation

Yeast’s optimal temperature for growth is 30°C and industrial ethanol production’s is 33°C. With an increased temperature – between 35 to 38°C – the yeast’s growth rate will be lower, and ethanol toxicity will increase. There is a cumulative effect of both high temperature and ethanol concentration on yeast inhibition. Choosing a robust yeast able to manage such temperature levels is essential to optimize the fermentation performance.

Osmotic pressure can also stress yeast in the fermentation process. Osmotic pressure is the pressure related to concentration differences of the molecules between the medium and the inner part of the yeast. Many molecules can contribute to osmotic pressure in the medium, the main ones being sugars: monomeric sugars (glucose, fructose), dimeric sugars (maltose, sucrose) and trimeric sugars (maltotriose). The level of osmotic pressure in a medium will affect ethanol yield as glycerol can be overproduced in osmotic stress conditions. Osmotic stress will also affect ethanol productivity by partially inhibiting yeast growth. Maintaining a level of osmotic stress below a critical value will lead to fermentation performance improvement.

In the case of grain fermentation, adjusting enzyme hydrolysis to yeast kinetics can help in maintaining a lower level of osmotic stress. In the case of sugar fermentation – cane or beet – an optimized fed-batch strategy avoiding high sugar levels will lessen impact of osmotic stress.

Lastly, pressure can also be a physical stress for yeast when the value is over 2-3 bars. Hydrostatic pressure at the bottom of fermentor increases by 1 atmosphere (1 bar) for every 10 m of fermentor height. To reduce pressure stress, the height of fermentors is usually under 20 meters. Once again, choosing a robust yeast will limit the effect of this stress and the consequences.

Chemical fermentation stress

Organic acids – mainly lactic and acetic acids – can be produced by the contaminants or can be present in the raw material itself. Acids will inhibit the yeast and have effect on ethanol productivity and yield. The associated pH is also an important parameter of fermentation stress as the toxic form of a couple acid/base is the acid form (releasing one H+ when entering the cell). Working pH and comparison with pKa of the organic acid is a major tool to optimize ethanol productivity, yield, and ethanol titer.

Each gram of organic acid produced by the contaminants will directly decrease ethanol. Reduction of contamination is a major step to limit organic acid inhibition.

Lastly, when a nutrient for yeast growth is missing, yeasts undergo stress due to nutrient limitations. This impairs growth and can affect both yield and productivity.

For instance, if nitrogen is limiting, fermentations will stall leading to yield losses (yeast consists of 8-10% w/w nitrogen on dry cell basis). Nitrogen limitation will also have a direct impact on ethanol productivity as the yeast population is limited and kinetics are slowed. Working without nutritional limitation – except oxygen as we want to optimize ethanol production in fermentation – will help to have a robust yeast to maintain a high ethanol productivity and yield even at high ethanol concentration.