Fostering innovation by outsourcing microorganism and process development

As industries are shifting towards more sustainable solutions for all applications, players are seeking alternatives to their current productions. This

Industrial biotech for a sustainable industry

Important changes are taking place at this very moment: current generations want to prosper without jeopardizing the future generations’ ability to meet their own needs. Thus, every industry sector is rethinking its productions ways, to meet consumers’ demands and regulations’ standards for more sustainable and healthy productions. What if this trend towards modernization of production could increase competitiveness while reducing environmental footprint?

Continuous and rapid flows of innovations and technologies are rising in all fields – big data, massive gene transfer, IA, bioinformatics. Without collaboration, seizing the opportunities offered by these advances is nearly impossible. For instance, looking at a product’s entire life cycle could generate new business models and opportunities: municipal waste or co-products from one industry are becoming raw materials for another one. By decompartmentalizing business sectors, new value-added chains emerge and are structured. There are still many end-of-life products to be recycled and biomass to be exploited in a reasoned way to produce locally bio-based products more respectful of the environment.

At Leaf, we are committed to accelerate this transition to a more sustainable industry. We believe in the potential of fermentation as an economically viable route to produce eco-friendly products with improved performances. We nurture partnerships from all horizons are craving to challenge our knowledge and to push boundaries for developing new processes for renewable productions.

Leaf and Lesaffre teams have a long experience in industrial fermentation. We have been developing, producing, and bringing to market fermentation-based products for over 170 years. Driven by the conviction that fermentation is one of the answers to today’s challenges, we collaborate with players from all sectors to make industry more sustainable.

We support our partners to turn their biobased projects into industrial reality. Working together, we combine our strengths and expertise to iteratively develop fermentation solutions adapted to market needs. We rely on the infinite potential of microorganisms to convert biosourced feedstocks and industrial waste into biobased molecules that meet the specifications of each application.

Our know-how and flexibility allow us to accompany our partners, whatever the stage they are at, on this path of development and industrialization of microorganism, biobased molecule, or product.

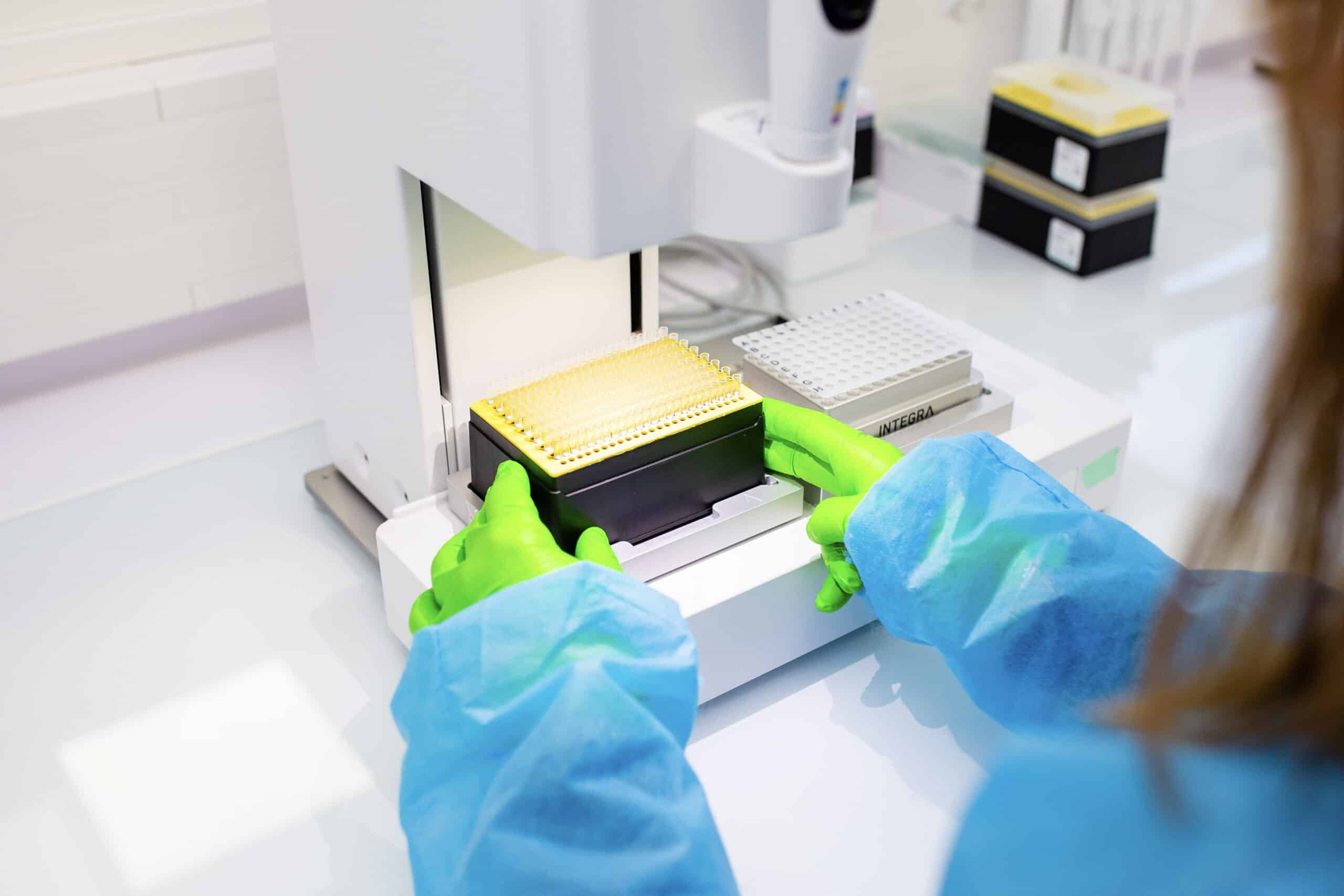

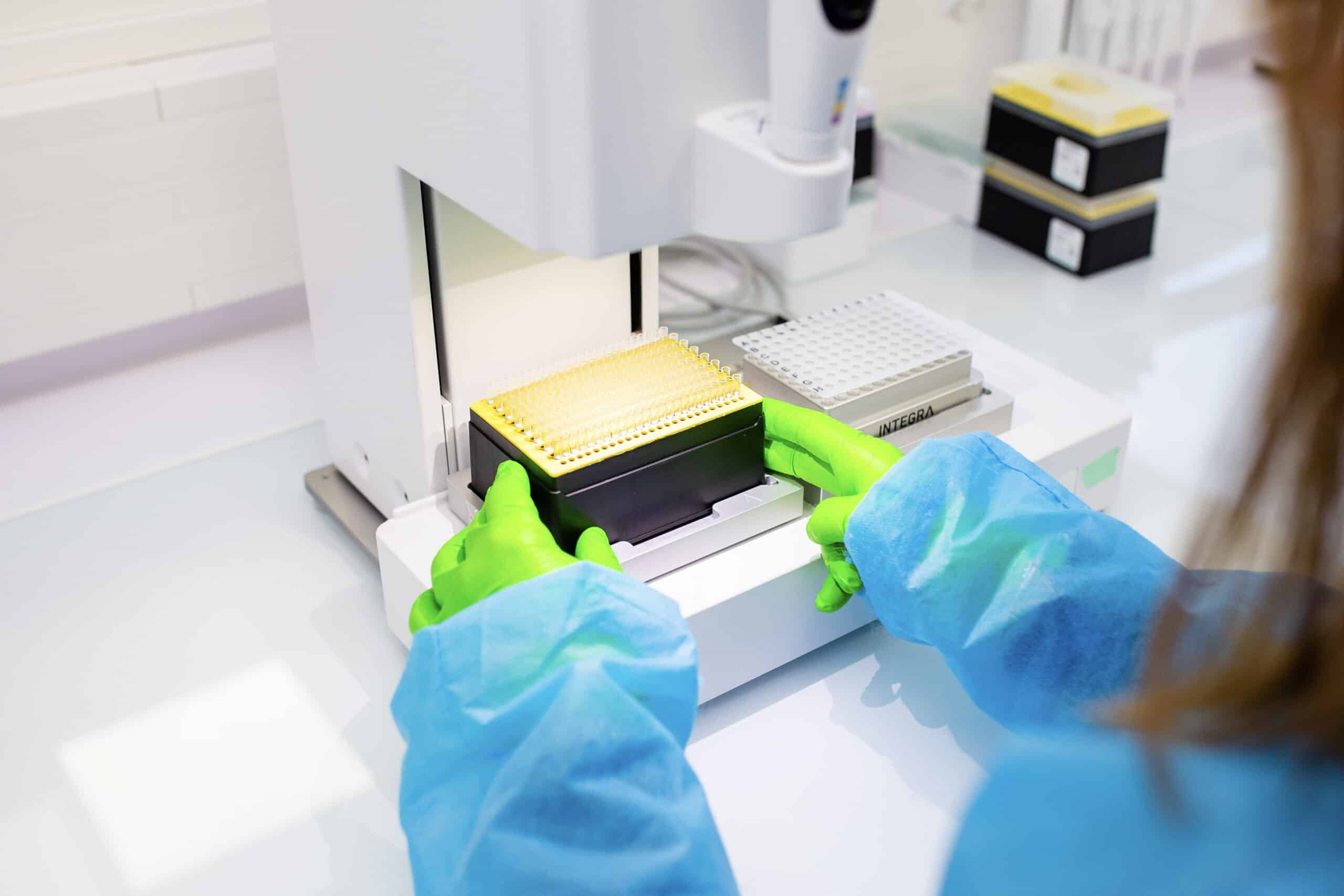

Drawing upon Lesaffre’s R&D and our industrial fermentation expertise, we develop industrial strains with high robustness that can handle the conditions of industrial processes.

Within Lesaffre’s R&D facilities, development and optimization of a fermentation process to produce biomass and/or molecules mimicking industrial conditions.

A scale-up performed in a commercial plant in order to have a process book representative of the industrial process conditions (e.g., industrial raw materials and equipment) and thus determine if the process is economically viable at commercial scale.

Contract fermentation of proprietary GMO and non-GMO microorganisms from pilot to commercial scale using Lesaffre technology and plants network.

A global supply chain compliant with local regulations.

Extensive experience and know how in industrial fermentation to support on-site production or commissioning.

Fostering innovation by outsourcing microorganism and process development

As industries are shifting towards more sustainable solutions for all applications, players are seeking alternatives to their current productions. This

Contract fermentation: a way to successfully achieve industrial production

Biotechnology consists of combining scientific and technological processes with living organisms to create new useful properties. Its contribution to the

Industrial sustainability: solutions and technologies

It seems that no matter where you look, somebody is talking about sustainability: from recycling to sustainable sourcing to industrial

At Leaf, we are convinced that the key to success for a competitive biobased product is to integrate sustainability throughout the value chain. Thus, we collaborate with experts in their field: producers of raw materials, technology developers, technology providers, and manufacturers, to think in complete value chains.

That is why, our business model is flexible and adapts to the project. We can also partner in the form of a service agreement, or as a joint-development or consortium.