Biotechnology consists of combining scientific and technological processes with living organisms to create new useful properties. Its contribution to the environmental transition is significant within the bioeconomy. Many products from the petrochemical industry can be replaced by biobased products with the use of industrial fermentation.

The industrial fermentation market was valued at $62B in 2021, with an expected growth rate of 6.6% between 2023 and 2030 (1). A lot of now allow the use of bio-based alternatives in many fields, via fermentation : bioethanol, construction materials, adhesive resins, plastics, cosmetics, or textiles.

While the benefits of industrial fermentation are well established, scaling-up remains a major challenge in the fermentation process, as production conditions differ from lab-scale to commercial-scale. Contract fermentation is therefore a solution to be seriously considered for start-ups and industrials who wish to succeed in scaling up, thanks to production outsourcing.

Contract fermentation to complete the whole industrial fermentation process

Industrial fermentation is a multi-step process

Whether it is to validate a proof of concept, produce pre-series, reach an industrial production volume or be able to sell production licenses, having in mind the different steps and stakes of the whole industrial fermentation process is essential to successfully complete the project:

- Strain selection, optimization, or development, depending on the final expected properties

- Optimization of fermentation processes, in order to reach conditions that can be scaled-up to commercial production

- Scaling up, during which fermentation volumes are progressively, yet significantly increased to control and validate the technical and economic viability of the developed process at scale

- Commercial production of the proprietary microorganisms in large volumes to meet business needs.

Each step is important, and nothing can be left to chance. Drawing upon industrial fermentation specialists is a way to ensure a project’s success, as it will help making the right choices early in the process.

Contract fermentation to externalize industrial production

Industrial service providers offer support for several or all stages of the fermentation process, sometimes including contract fermentation. Contract fermentation – also known as contract manufacturing – consists in entrusting the microorganism production at commercial scale, to a partner who provides an outsourced service under contract.

Contract manufacturing is an ideal solution for many players because owning or having quick access to the necessary technical and human resources for production, even in small volumes, stays limited. Most of today’s available facilities are bench or pilot-scale, while the demand for commercial-scale is hardly met (2).

Contract manufacturing: benefit from state-of-the-art means and expertise

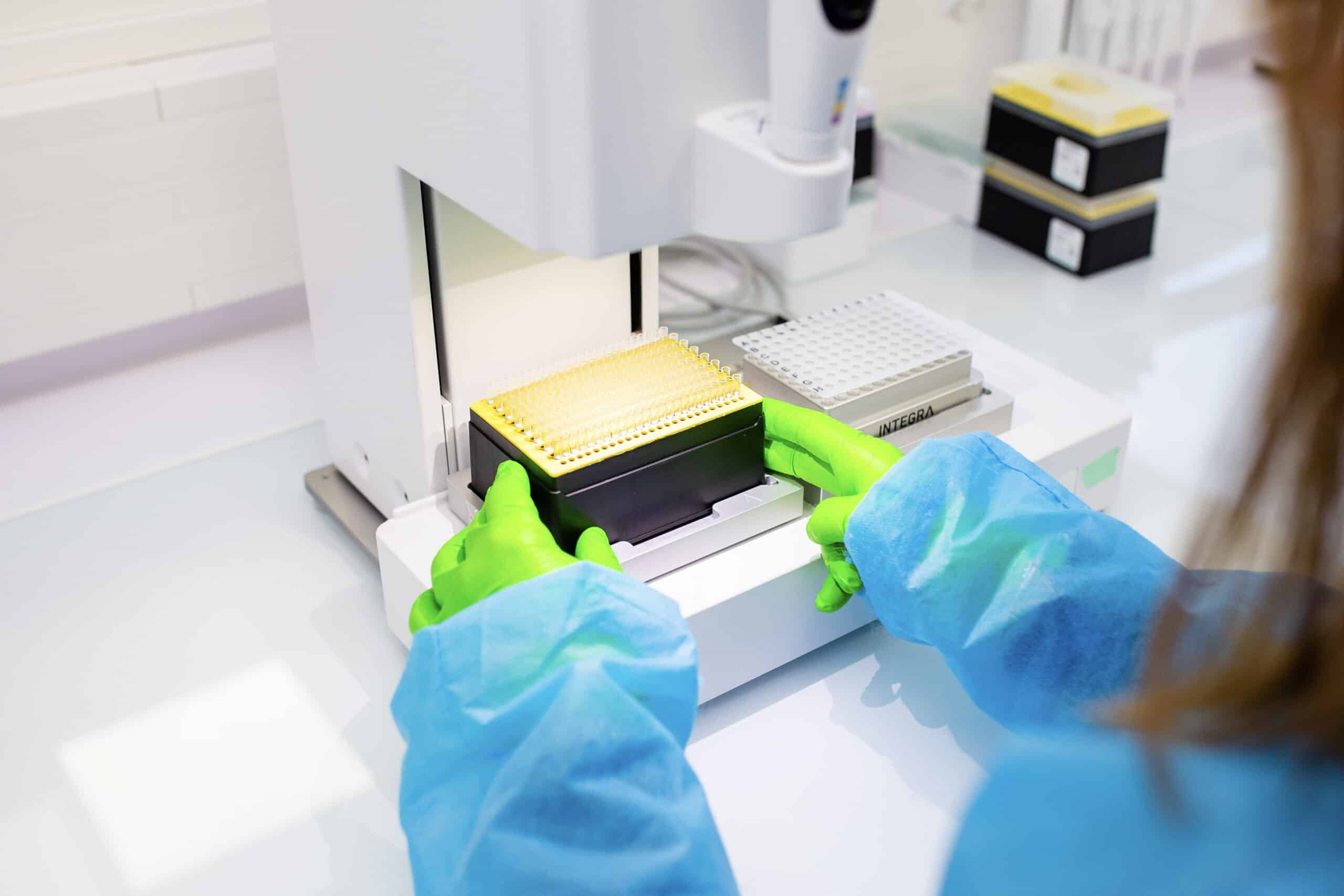

Benefiting from contract fermentation to access facilities and equipment

Dealing with a provider for the industrial-scale production of microorganisms allows to benefit from all the material elements that it owns. Thus, it makes it possible to carry out commercial production without in-house capacities and without disrupting existing operations.

Having access to such infrastructures offers many advantages, such as:

- Reaching a much higher production capacity

- Easily increasing production volumes from time to time to meet a potential peak of activity

- Where appropriate, producing in several locations in order to geographically break down production and facilitate distribution and/or export streams

- Having access to these equipment also allows for shorter production times. At the beginning of the project, having infrastructures ready to use avoids the time-consuming facility construction or acquiring phases. In further advanced projects, contract manufacturing also allows for shorter production times through the fully-mastered infrastructures of the partners.

As the industrial fermentation market and its various applications are evolving quickly, reactivity is essential to stand out in the competitive landscape. Outsourcing microorganism production is therefore a clear advantage for manufacturers seeking to maintain competitive time-to-market.

Contract manufacturing's second benefit: expertise

Having access to high-quality infrastructures is not the only advantage linked to contract fermentation. Outsourcing industrial microorganism production also allows to benefit from the expertise of the selected service provider and from its dedicated human resources.

Companies that specialize in industrial fermentation are staffed with experts, and most of the time acquired a multitude of complementary skills through the diversity of handled projects, knowledge sharing or strong internal mobility. These human resources are here to advise and challenge the projects of the companies they support. Moreover, these available skills are very specific – genetic, legal, industrial – with, sometimes, a more thorough and comprehensive knowledge compared to what could be expected in-house.

Some service providers, are able to offer support throughout the entire fermentation process: when they have been solicited at the beginning of a project, it may be natural to trust them for the final production via contract manufacturing, in order to perpetuate a real partnership through co-construction and a common vision.

Limit uncertainty of microorganisms production: the reassuring choice of externalization

Contract fermentation as a way to minimize financial risk

Even though a contract fermentation service may seem to have a higher cost than in-house production, outsourcing the production of microorganisms remains financially attractive for three main reasons:

- Setting up production is quicker and easier. Finding an access to suitable infrastructures can be time-consuming and the setting up of the fermentation process in-house can be laborious. This time saved thanks to contract fermentation is also financial savings.

- By using contract fermentation, no material investment is necessary, and the client only pays for the production that is actually produced. Thus, in case of technical problem or drop in activity, production can be suspended without having to pay fixed costs.

- The flexibility and the expertise provided by the fermentation contract, whether on volume adaptation or on fermentation process modification, also save time and money.

Contract fermentation also reduces concerns

In addition to avoiding significant investments and limiting financial losses, using the service of a provider for the production of microorganisms allows to offload challenges that can be time-consuming and complex to manage internally. The responsibility for the success of the project is indeed shared with the partner:

- The customer is relieved from equipment set-up and human skills recruitment

- The customer is not responsible for the technical issues related to the installation and does not have to manage them

- The quality and stability of the production are guaranteed by the contract, through the expertise and the quality control methods of the provider

- The flexibility provided by contract fermentation means that the customer doesn’t have to rethink his entire business to adapt the production process: he can rely on the support of his service provider

Full-scale microorganism production as the final step of the production process is crucial yet challenging. Relying on contract fermentation when it comes to bio-based production ensures having access to commercial quantities in a controlled timeframe while minimizing the risks link to full-scale production. Relying on the expertise & existing facilities of a trusted partner is not only cost effective, but it can boost your productivity and competitiveness in crowded markets.

With a thorough understanding of the full process and stakes, we are able to support our partners in completing their commercial productions. Our contract fermentation services leverage our expertise, experience, and the most recent advances to reach the full-scale production of your proprietary microorganism delivered on-time, in full.