The effects of toxicity on ethanol production

The production of ethanol is often impacted by the toxicity of feedstocks used. It is essential to understand feedstock-related toxicities’ adverse effects on ethanol production and to take measures to minimize their effects. Feedstock toxicity, a challenge for productivity and yield Organic acids, the principal inhibitors of fermentation Organic acids – such as lactic acid, […]

Troubleshooting checklist for industrial ethanol production

Ensuring smooth operations and complete fermentations in ethanol production requires an effective troubleshooting strategy. To guarantee a successful approach in ethanol plants, there are several aspects to consider: knowing the plant’s baseline, spotting critical changes, identifying the trouble source, having an effective problem-solving strategy, and knowing who to turn to for support in such happenings. Knowing your production […]

The effects of temperature on ethanol production

The success of ethanol production relies, partly, on various factors that can affect fermentation, with temperature playing a pivotal role. Yeast performance in converting feedstocks to ethanol is strongly linked to fermentation temperature, as it can only satisfy its needs under a suitable temperature environment. In this article, we will explore the effects of temperature […]

How can advanced yeast improve industrial ethanol plants’ performances?

In the field of industrial ethanol production, maximizing efficiency and yields while minimizing costs and environmental footprint are constant goals. One of the key factors in addressing these challenges lies in the choice of yeast. Advanced yeasts are genetically engineered to enhance their ethanol production capabilities. Those genetic modifications consist of carefully altering the yeast’s […]

How to perform optimal ethanol fermentation? 7 key points

Producing industrial ethanol requires careful attention to detail and a thorough understanding of the fermentation process. Optimal ethanol fermentation can be achieved through various optimization factors: choice of the yeast, fine tuning of process parameters, contamination control, and so on. 1. Selecting the right yeast strain Different yeast strains have different abilities to ferment various […]

The benefits of complex yeast nutrients for your industrial ethanol production

Yeast nutrition is a key factor in the productivity and viability of industrial ethanol production. In such production processes, reaching the highest yields, securing fermentations, and improving consistency are essential conditions to achieve operational gains and remain viable. From individual nutrition to complex yeast nutrient packages Historically, industrial ethanol producers have been testing their mashes […]

How does fermentation stress affect plant profitability? – Through the study of industrial ethanol production

Like all biochemical processes, we can evaluate fermentation performance using the following 3 Key Performance Indicators (KPIs): productivity, yield and titer. These 3 KPIs have a direct impact on industrial ethanol production cost and thus plant profitability. All fermentation stresses leading to an impact on one or several of these KPIs will also impact plant […]

How to choose the ethanol yeast?

Yeast is a key element in industrial ethanol production and each cell works like a production unit. From fermentable materials, yeast produces the major product ethanol and several co-products, such as CO2 and glycerol. As in the case of the production unit, the choice of yeast is an important technological decision that will have a […]

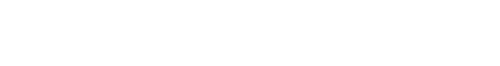

What is Yeast?

Yeast is a key element in the production of industrial ethanol, but do you know the specificities of this microorganism? Yeast is a unicellular fungus Yeast belongs to the family of the fungi. It consists of a large and diverse group of eukaryotic organisms, i.e. they possess organelles that divide the cell space into specialized […]

De-risking fermentation

“2014 was the year of second generation ethanol with the openings of several plants in North and South America. A number of other multi-partner global projects have also been announced or are currently under construction by major actors of the cellulosic ethanol scene. In the US alone, the E2 advanced biofuel market report published in […]